DTF printing changes the way you create custom T-shirts through its amazing versatility at a great price. What is DTF printing? Direct To Film printing lets you print on T-shirts made of cotton, polyester, or blends whatever their color. This makes it perfect to expand your business without limits.

Looking for an economical solution that gives professional results? DTF printing has become very popular among garment decorators and with good reason too. The DTF printing process transfers designs onto a thin film and then heat-presses them onto fabrics. DTF transfers work on many materials without the need for separate transfer paper or special inks.

DTF prints resist cracking, peeling, and fading even after many washes. This print-on-demand friendly method works faster and easier than other options like DTG printing that needs fabric pre-treatment. DTF printing gives you high-resolution results with bright colors and fine details that work on everything from cotton to nylon. This makes it perfect if you want to start a custom apparel business or grow your current one.

Understanding What DTF Printing Is

Image Source: Impressions Magazine

DTF stands for Direct-to-Film, a printing method that's becoming the top choice for custom apparel businesses. This innovative technique connects traditional printing methods with modern digital approaches. It gives you the perfect mix of quality, versatility, and economical solutions.

What is a DTF transfer and how it works

DTF transfer uses a two-step process. Your design gets printed onto a special PET (Polyethylene Terephthalate) film instead of fabric. The PET film measures about 0.75mm thick and transfers designs beautifully.

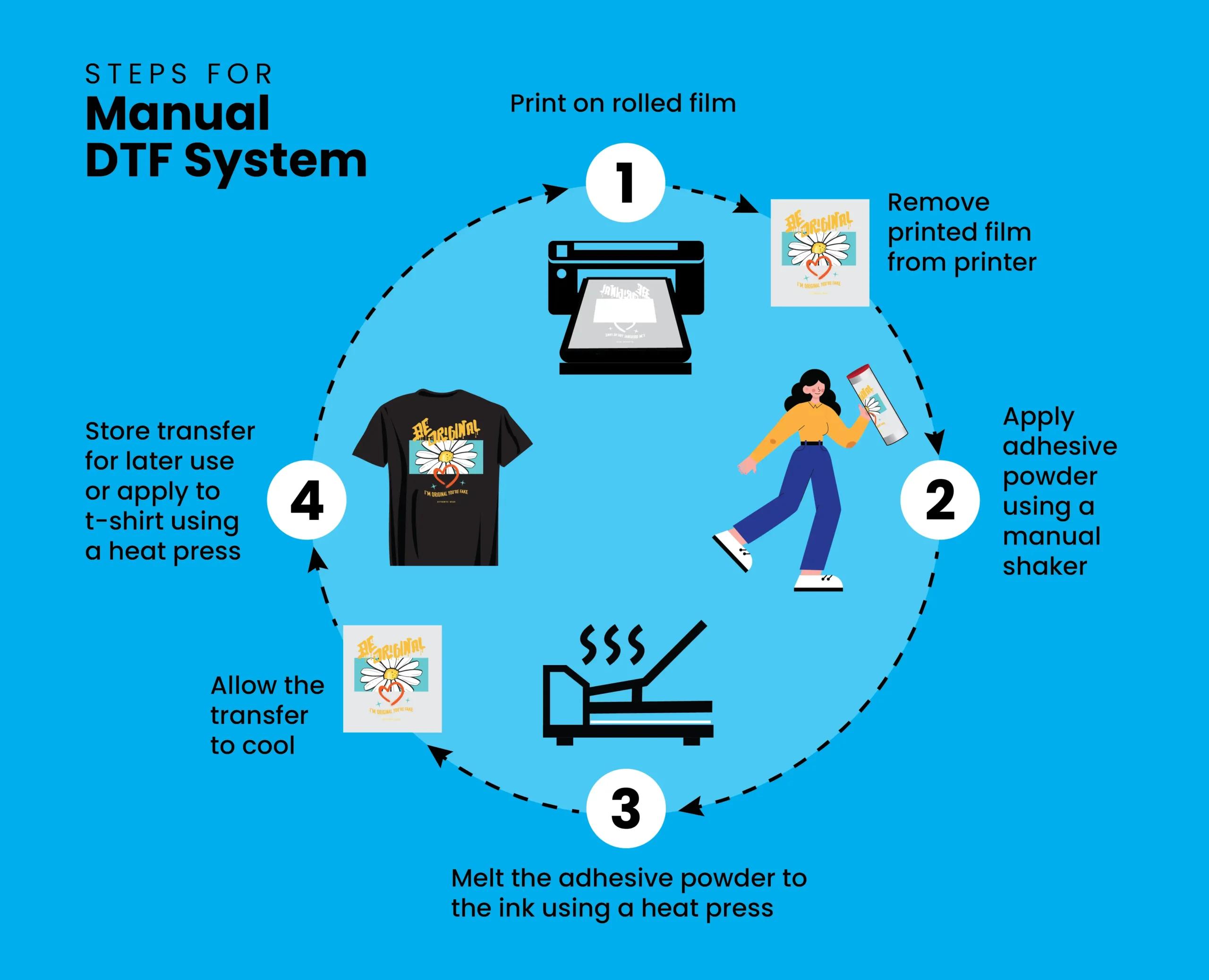

The process follows a specific sequence:

- Design Creation: First, create your artwork using design software like Adobe Illustrator or Photoshop.

- Film Printing: Your design gets printed onto the PET film using special DTF inks. A white layer often goes down first—creating that perfect foundation for vibrant colors, especially on dark fabrics.

- Adhesive Application: Hot-melt adhesive powder gets evenly applied to the wet ink, helping your design bond perfectly to the fabric.

- Curing: The film with powder gets heated up, melting the adhesive and creating your transfer.

- Heat Transfer: Finally, a heat press applies your design to the garment, activating the adhesive and transferring the ink.

When you're done, just peel off the film and there it is—a vibrant, durable print that looks professional every time.

What Makes a DTF Printer Special

A DTF printer is built (or modified) specifically to print onto film instead of paper or fabric. Most are adapted inkjet printers with specialized ink systems that include CMYK colors plus white ink.

These printers work differently from Direct-to-Garment (DTG) machines. DTF prints onto film first, while DTG goes straight to fabric. This difference creates several benefits:

No fabric pretreatment: You can skip the preparation step that DTG requires. DTF transfers work on various materials right away.

Fabric flexibility: DTF prints look great on cotton, polyester, blends, nylon, leather, and even glass or wood. DTG mainly works with cotton.

Double print head technology: Your printing speed and output increase thanks to double print heads in many DTF printers.

Here’s a quick snapshot of DTF’s applications:

- Casual Apparel: T-shirts, hoodies, tank tops.

- Professional Wear: Branded polos, jackets, uniforms.

- Accessories: Hats, tote bags, headbands.

- Sportswear: Jerseys, workout sets.

- Decorative Items: Throw pillows, fabric patches.

Why DTF is modern apparel printing's perfect match

Today's apparel businesses just need flexibility, quick results, and quality. DTF printing delivers all three.

Remarkable versatility makes DTF stand out. You can print on any fabric color or type. This opens endless possibilities for your product line. Your business can grow without buying multiple printing systems.

Economical solutions make DTF great for small to medium runs. Setup costs stay low compared to screen printing. You won't need expensive pretreatment solutions, so your profit margins improve.

Vibrant colors and details set DTF apart. Complex artwork, gradients, and fine details come out beautifully - areas where other methods fall short.

Production efficiency gives you another advantage. You can create transfers before having actual garments. This helps streamline processes and fill orders faster.

Smart T-shirt business owners choose DTF printing. It helps meet customer needs in a variety of situations while keeping quality high and profits strong.

Step-by-Step Breakdown of the DTF Printing Process

Image Source: ColDesi

DTF printing transforms artwork into wearable designs through a series of precise steps. You can achieve professional-quality transfers by understanding each phase of the process.

Design preparation and file formats

The right file format and specifications make DTF-ready artwork possible. Your design needs high-resolution (300 DPI) to ensure sharp, detailed prints. Vector files (AI, EPS, PDF, SVG) excel for logos and text, while raster files (PSD, PNG, TIFF) work well with photographic elements. RGB (screen colors) should become CMYK (print colors) before finalizing to prevent unexpected color changes in the final print. A transparent background prevents the "box effect" on garments and optimizes results.

Printing on PET film with CMYK + white ink

The next step prints your design onto specialized PET film. This 0.75mm thick film has unique transfer properties perfect for DTF. The design appears as a reverse/mirror image on the film using DTF-specific inks. A white layer covers the colored areas to create a solid base, which matters especially on dark garments. DTF printing systems typically use five ink colors—Cyan, Magenta, Yellow, Black, and White—to produce vibrant images.

Applying and curing adhesive powder

The wet ink needs hot-melt adhesive powder. Small batch producers can pour the adhesive evenly across the film and rock it gently for uniform coverage. Larger operations benefit from automated powder shakers that deliver consistent results. Remove excess powder and heat the film to melt the adhesive. The melting happens at 150-160°C (302-320°F) for 2-5 minutes until an "orange peel" texture appears.

Heat pressing onto garments

A quick pre-press of 2-5 seconds removes moisture and flattens the printing area. Place your DTF transfer with the adhesive side down on your garment. The press should run at 310°F/155°C with medium to high pressure for 12-15 seconds. Polyester fabrics need lower temperatures of 275-300°F (135-149°C) to avoid scorching. Heat activation bonds the design permanently to the fabric fibers.

Peeling and post-pressing

The peeling choice comes down to hot (removing while warm) or cold (waiting until cool). Most commercial providers choose hot peeling to save time. The process needs one final step - cover the transferred design with parchment paper and press for 15 more seconds. This last press enhances durability and softness while reducing shine. Washing the printed garments inside out in cold water helps them last longer.

Comparing DTF with Other Printing Methods

Image Source: Sublicool

You just need to understand how DTF compares to other options to make the best choice for your T-shirt business's ideal printing method. Each technique brings unique advantages based on your business needs.

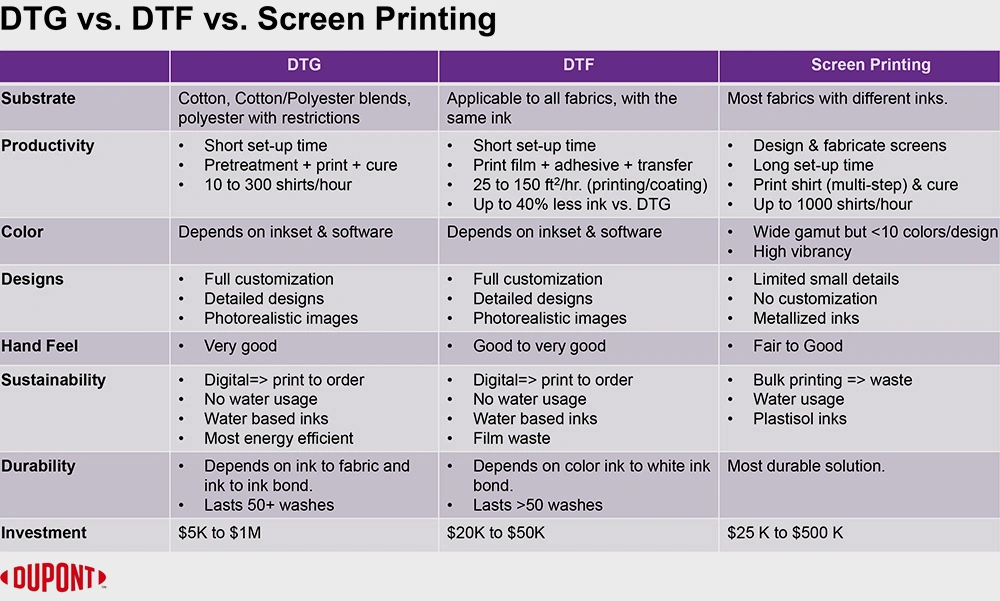

DTF vs DTG: cost, quality, and fabric compatibility

Direct-to-Film and Direct-to-Garment printing are two digital approaches that are different from each other. DTF works on almost any fabric - cotton, polyester, blends, leather, and even nylon. DTG works best on natural fibers like 100% cotton and doesn't do well with synthetic materials.

Both methods deliver excellent print quality in different scenarios. DTF shines with vibrant colors and sharp details because the ink stays on top of the fabric. The prints might feel stiff at first but soften after washing while keeping their color vibrant. DTG feels softer right away since the ink soaks into the material, but colors might look less vibrant on dark fabrics.

Both methods work great for on-demand fulfillment without minimum orders. DTF sets up faster because you don't have to pretreat the fabric like DTG needs for dark garments.

DTF vs Screen Printing: setup and scalability

Screen printing leads the bulk apparel production, but DTF offers better options for some business models. Screen printing needs separate screens for each color, which takes more prep time and costs more upfront. DTF doesn't need this setup, making it perfect for small batches or colorful designs.

Orders over 100 pieces make screen printing more economical due to scale benefits. The cost per unit drops substantially as quantity goes up. DTF prices stay the same no matter the volume, which works better for small-to-medium runs.

Screen printing creates bold, lasting prints with a texture that customers love. DTF handles complex designs and photo-realistic images better than screen printing ever could.

Take a look at our article that provides an in-depth comparison between DTF and Screen Printing.

DTF vs Sublimation: material limitations and color vibrancy

Material compatibility sets these methods apart. Sublimation mostly works with polyester or polymer-coated materials and does best on white or light-colored fabrics. DTF works on almost any material, no matter the color.

Both use CMYK color models, but DTF has white ink as a base layer, which lets you create vibrant designs on dark materials. Sublimation can't make white elements because it doesn't use white ink. Sublimation prints become part of the fabric with no texture, while DTF sits slightly above the material.

Large DTF prints might reduce how well the garment breathes because of the adhesive layer. Sublimation keeps the fabric's natural airflow.

DTF vs White Toner: ease of use and cost

White toner printing and DTF both use heat press transfers, but they work differently. You'll just need to print almost daily with DTF to prevent clogging. White toner printers can sit unused for weeks without problems since they use toner instead of ink.

Starting costs vary a lot. White toner systems cost between $3,000.00 - $10,000.00. DTF printers range from $3,000.00 for manual systems to $50,000.00 for automated setups. DTF costs less per print over time.

White toner can decorate mugs, wood, metal, and other hard surfaces besides fabrics. DTF transfers mainly work on textiles.

Pros and Cons of DTF Printing

Image Source: Screen Printing Mag

Each printing method has its own advantages and limitations. You can make better decisions for your custom apparel business by knowing DTF printing's strengths and weaknesses.

✅ Pros: all-fabric compatibility, vibrant colors, no pretreatment

DTF printing's versatility makes it stand out. You can print on cotton, polyester, nylon, treated leather, denim, and even silk. This wide range means you won't need multiple printing systems for different fabrics.

Your designs will pop with DTF transfers. Water-based pigment inks over a white underbase create rich colors that stay vibrant even on black fabrics. The prints look crystal clear and capture every detail perfectly.

DTF printing doesn't need the pretreatment sprays that DTG printing requires. This saves money and time while making your production smoother.

Other notable benefits include:

- Better durability - DTF transfers last through 30-50 industrial washes without cracking or fading

- No color restrictions - Print photorealistic graphics and complex color gradients with no limits

- Budget-friendly - Makes sense for small to medium orders with minimal setup costs

- Quick production - Faster turnaround times than traditional methods like screen printing

❌ Cons: thicker feel, requires heat press, can be messy DIY

DTF printing has some drawbacks. The prints feel slightly thicker on fabrics. The adhesive layer creates a more plasticky texture than DTG or screen printing, which might affect thin fabrics' breathability and comfort.

You'll need the right equipment to succeed. A heat press plays a crucial role in applying DTF transfers correctly. DIY operations might find the powder adhesive messy without proper technique.

Additional challenges include:

- Regular maintenance - Print heads need constant use and cleaning to avoid clogging

- Good ventilation - The process creates polymer fumes that need special air filtration

- Risk of yellowing - High-temperature ironing might turn white ink yellowish

Every printing method has its trade-offs. DTF's mix of quality, versatility, and affordable pricing makes it a smart choice for many T-shirt businesses.

Is DTF Printing Right for Your Business?

Your T-shirt business's success depends on picking the right printing technology. DTF printing might be exactly what you need to achieve your business goals.

Looking for Speed and Flexibility in Production?

DTF printing excels in efficiency for businesses that need quick results. You can create 10-20 items every hour, which works great for smaller orders that need fast delivery. Unlike screen printing that needs separate screens for each color, DTF lets you switch designs quickly without extra setup. The market demands and customer requests can be handled faster this way.

DTF also lets you set up an assembly-line production system. You can print designs, cure transfer film, and run heat presses all at once. This setup maximizes your workflow efficiency for custom orders.

Need to Work with Different Fabric Types?

The versatility of DTF printing with fabrics makes it stand out. Your product line can include items made from cotton, polyester, blends, nylon, leather, and even silk. DTF transfers create strong bonds with many fiber types, so you can expand beyond simple t-shirts.

This versatility saves you money since you won't need multiple printing systems. The long-term cost benefits for your business are significant.

Want to Keep Setup Costs Low?

Small-to-medium businesses find DTF printing economical because of its low startup needs. The process needs only simple operational training, which keeps labor costs minimal. The technology doesn't require specialized technical expertise, so training expenses stay low.

You have options if you're worried about the original investment. Start by using a DTF transfer provider or buy your own equipment based on what your budget allows.

Best Times to Pick DTF Over Other Methods

DTF works best when you need:

- Material flexibility: It's perfect if you use different types of fabrics beyond cotton or polyester

- Small batch efficiency: Small print runs and custom orders become more cost-effective with DTF

- Vibrant designs on dark fabrics: DTF's white ink base creates better colorful prints on dark materials

Screen printing might be a better choice if your focus is only on large-scale production runs because it's more economical at that scale.

How to Get Started with DTF Printing

Image Source: ColDesi

Let's take a closer look at DTF printing. You have two main ways to start: buy your own equipment or work with experienced providers.

Buying your own DTF printer and setup

Your own DTF equipment puts you in control of production. A detailed DTF setup has these key components:

- A specialized DTF printer (modified Epson models are popular choices)

- High-quality DTF inks (CMYK plus white)

- PET film designed specifically for DTF printing

- Adhesive powder and applicator

- Curing system (oven or heat gun)

- Heat press for transfer application

The original investment runs from $3,000 for manual systems to $50,000 for fully automated setups. Starter kits give beginners the equipment and supplies they need to start production immediately.

Outsourcing to a DTF transfer provider

Not everyone needs their own equipment. Working with specialized DTF transfer providers brings several benefits:

Lower original investment - You won't need expensive equipment purchases and can focus your money elsewhere. Outsourcing eliminates setup costs for equipment, maintenance, and waste management.

Production flexibility - You can adjust order quantities based on your business needs without worrying about unused equipment during slow periods.

Technical expertise - Professional printing companies have skilled technicians who know the latest technology and techniques. This ensures high-quality prints with fewer mistakes.

Tips for choosing the right supplier

Think over these important factors when picking a DTF supplier:

Product quality - Ask for samples to check color vibrancy and durability. Good DTF film should excel in color and transfer effects.

Technical support - Look for suppliers who offer professional information and help after sales.

Product range - Pick vendors who offer different sizes and types of materials.

Turnaround time - Choose suppliers who respond and deliver quickly.

Best practices for first-time users

These steps will help you succeed with DTF printing:

Maintain your workspace - A clean, dust-free area prevents imperfections in designs.

Follow regular maintenance - Users with their own printer should check nozzles daily and shake inks to prevent clogging.

Test before scaling - Small test batches should come before larger production, especially with new fabrics or techniques.

Ensure proper ventilation - Melting adhesive powder releases fumes that need good airflow.

Conclusion

DTF printing is a revolutionary force for T-shirt business owners who want versatility, quality, and affordable solutions. This piece shows how this innovative method creates vibrant designs on almost any fabric. You won't need pretreatment or worry about material limitations.

The technology works great with many fabrics. You can expand beyond simple cotton shirts to polyester, nylon, leather, and silk—all with one printing system. On top of that, DTF prints will give your customers products that stay vibrant even after many washes.

DTF printing gives small to medium businesses huge advantages over traditional methods. Quick setup and fast turnaround times make it perfect for custom orders and on-demand fulfillment. The exceptional color quality lets you create complex, photorealistic designs that make your products stand out.

Your business model and production volume should guide your choice between buying equipment or working with a supplier. Many entrepreneurs start by outsourcing to balance quality and investment perfectly. Want DTF transfers that work? Order by size or upload a gang sheet — we print, pack, and ship fast. No weird rules, no fluff. Just quality prints and good service.

DTF printing has become a 5-year old versatile and reliable solution in the custom apparel industry. The technology keeps evolving and gives T-shirt business owners available entry into professional-quality printing with great results. DTF printing could be the boost your business needs to reach new heights of success.

FAQs

Q1. How does DTF printing compare to other T-shirt printing methods? DTF printing offers unique advantages such as compatibility with various fabric types, vibrant colors on dark materials, and no need for pretreatment. It's more versatile than DTG, more cost-effective for small runs than screen printing, and works on a wider range of fabrics than sublimation.

Q2. Is DTF printing a profitable business venture? DTF printing can be highly profitable due to its low setup costs, flexibility, and efficiency for small to medium-sized orders. It's particularly suitable for print-on-demand and customized apparel businesses, offering potential for high profit margins per print.

Q3. What equipment is needed to start a DTF printing business? Essential equipment includes a DTF printer, PET films, DTF printing software, specialized inks, hot-melt adhesive powder, an automatic powder shaker, a heat press machine or curing oven, and quality control tools. You can start by either investing in your own setup or outsourcing to a DTF transfer provider.

Q4. What are the main advantages of DTF printing for T-shirt businesses? Key advantages include all-fabric compatibility, vibrant colors even on dark garments, no need for pretreatment, cost-effectiveness for small to medium runs, and the ability to produce detailed, photorealistic designs. It also offers fast turnaround times and flexibility for custom orders.